- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 999 Author: Site Editor Publish Time: 2025-07-24 Origin: Site

Compressed gas cylinders hold many kinds of gases under pressure. Each gas is different and can be dangerous in its own way. Some gases turn into liquids inside the cylinders. Other gases stay as gases or are mixed with something else to keep them safe. The table below lists common gases found in compressed gas cylinders:

| Type of Gas | Description | Examples |

|---|---|---|

| Liquefied gases | Gases that turn into liquid when under pressure in cylinders | Propane, carbon dioxide, ammonia |

| Non-liquefied gases | Gases that stay as gas even when under high pressure | Nitrogen, helium, oxygen, argon |

| Dissolved gases | Unstable gases mixed in a solvent to make them safer | Acetylene |

People must always be careful when using these cylinders. Knowing about the gases and their dangers helps stop accidents.

Compressed gas cylinders can hold many kinds of gases. These include inert, flammable, toxic, and oxidizing gases. Each type has its own use and danger.

Always look at the cylinder labels very carefully. Do not use the color to know what gas is inside.

Store cylinders standing up and away from heat and fire. Keep flammable gases away from oxidizers. This helps stop fires and explosions.

Wear the right safety gear when using gas cylinders. Only people who are trained should handle them. This helps stop accidents and health problems.

Follow all safety rules and check cylinders often. Make sure you have emergency plans. This keeps everyone safe when using compressed gas cylinders.

Image Source: pexels

Compressed gas cylinders keep many kinds of gases inside. Each group of gas has its own use and features. The table below lists the main groups, what they mean, and some examples:

| Category | Definition | Examples |

|---|---|---|

| Inert | Gases that do not react easily with other substances | Argon, Helium, Nitrogen |

| Flammable | Gases that can catch fire and burn quickly | Acetylene, Propane, Hydrogen |

| Toxic | Gases that can harm or kill if breathed in | Carbon monoxide, Chlorine, Ammonia |

| Oxidizing | Gases that help other materials burn more easily | Oxygen, Nitrous oxide |

Inert gases do not mix or react with most things. People use these gases to stop reactions with air. Argon, helium, and nitrogen are common inert gases in cylinders. Argon helps in welding by making a safe cover for hot metal. Helium fills balloons and cools science tools. Nitrogen keeps food fresh and protects electronics when made. Inert gases do not burn or blow up, so they are safer than flammable gases. But they can push out oxygen in a room, which can make it hard to breathe if not used right.

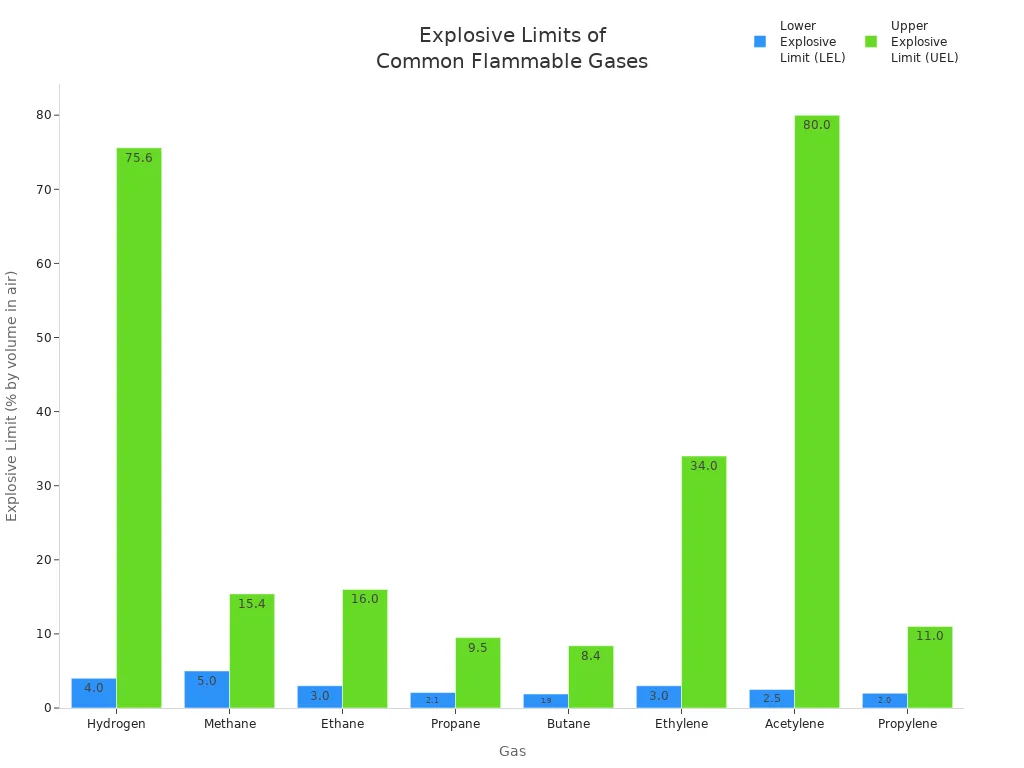

Flammable gases can catch fire and burn very fast. Acetylene, propane, and hydrogen are common flammable gases in cylinders. These gases are used for welding, heating, and as fuel. Hydrogen is very light and burns with a flame you can barely see. Propane is used for grills and heating homes. Acetylene is needed for cutting and welding metal. Flammable gases can blow up if mixed with air and touched by a spark or flame. The table below shows the lowest and highest amounts of gas in air that can explode:

| Gas | Lower Explosive Limit (LEL) % | Upper Explosive Limit (UEL) % |

|---|---|---|

| Hydrogen | 4.0 | 75.6 |

| Methane | 5.0 | 15.4 |

| Ethane | 3.0 | 16.0 |

| Propane | 2.1 | 9.5 |

| Butane | 1.9 | 8.4 |

| Ethylene | 3.0 | 34.0 |

| Acetylene | 2.5 | 80.0 |

| Propylene | 2.0 | 11.0 |

Tip: Always keep flammable gases away from heat and flames. Store them away from oxidizing gases like oxygen.

Toxic gases can make people very sick or even cause death if breathed in. Carbon monoxide, chlorine, and ammonia are toxic gases in cylinders. These gases are used for cleaning, water treatment, and making chemicals. Even a small leak can be very dangerous. Workers must follow strict rules when using toxic gases. OSHA gives rules for safe storage, labels, and handling of these gases. Cylinders must stand up straight, be tied down, and kept in places with good air flow. People need training and emergency plans when working with toxic gases.

Oxidizing gases do not burn, but they help other things burn faster. Oxygen is the most common oxidizing gas in cylinders. Nitrous oxide, ozone, chlorine, halogen, and fluorine are also oxidizers. Oxygen is used in hospitals, welding, and cutting metal. Nitrous oxide is used in medicine and food making. These gases help fires start and grow quickly. Keeping oxidizing gases near flammable gases can cause fires or explosions. Cylinders must be at least 20 feet apart or have a fire wall between them.

| Risk / Hazard | Description | Safety Measures |

|---|---|---|

| Fire and Explosion | Oxidizing gases can make fires start and spread quickly. | Store away from flammable gases and heat. Use barriers if needed. |

| Mechanical Failure | High pressure can cause sudden gas release if a cylinder or valve fails. | Inspect cylinders often. Use valve caps. Avoid extreme temperatures. |

| Contamination | Dirty or wet storage can cause leaks or corrosion. | Store in dry, cool, and clean places. |

| Toxic and Reactive | Some oxidizers are also toxic or react with other chemicals. | Use special cabinets and alarms. Keep away from incompatible gases. |

| Ventilation | Gas buildup can cause suffocation or fire. | Make sure storage areas have good airflow. |

Liquefied gases turn into liquid when under pressure in cylinders. Propane, carbon dioxide, chlorine, anhydrous ammonia, and nitrous oxide are common liquefied gases. These gases are both liquid and gas inside the cylinder. Propane is used for cooking and heating. Carbon dioxide is used in fire extinguishers and soda machines. Liquefied gases are very cold and can freeze skin if touched.

Dissolved gases are mixed with a solvent inside the cylinder. Acetylene is the most common dissolved gas. It is mixed with acetone and kept in a cylinder with special material. This keeps acetylene safe and stable. Acetylene is used for welding and cutting metal. Both liquefied and dissolved gases need special care. Cylinders must stand up, have labels, and be checked for leaks. Workers should wear safety gear and follow safety rules.

Note: Some gases fit in more than one group. For example, chlorine is both toxic and oxidizing. Always check the label and safety sheet before using any compressed gas cylinder.

Compressed gas cylinders can be very dangerous if not used safely. Many people get hurt each year because of these hazards at work. Knowing about these dangers helps keep everyone safe.

Flammable gases can catch fire or explode very easily. The main reasons for these risks are:

Leaks from broken valves, hoses, or regulators

Putting cylinders near heat, flames, or sparks

Handling cylinders the wrong way and breaking valves or tipping them over

High pressure that can make gas escape fast if a cylinder breaks

You can lower these risks by doing these things:

Keep cylinders away from heat, flames, and sunlight.

Keep flammable gases at least 20 feet from oxidizers like oxygen or use a fire wall.

Use chains or straps to stop cylinders from falling over.

Check valves and labels before using cylinders.

Open valves slowly and never put oil or grease on them.

Storing cylinders the right way and checking them often helps stop leaks and lowers the chance of fire.

Some gases are toxic or corrosive. Breathing in toxic gases can hurt your lungs, your nerves, or even cause death. Corrosive gases can burn your skin, eyes, or damage equipment. Dangers include:

Breathing in leaking toxic gases like ammonia or chlorine

Corrosive gases causing burns or breaking equipment

Handling cylinders the wrong way and letting gas out by mistake

Only trained people should use these gases. Always tag and take away leaking cylinders. Never use compressed gases to clean clothes or surfaces. Wear safety gear and follow all safety rules.

Oxidizing gases like oxygen do not burn but help other things burn faster. If oxygen leaks, it can make fires start and grow quickly. Asphyxiation hazards happen when gases push out oxygen, making it hard to breathe. To stop these dangers:

Store cylinders standing up in places with good airflow

Use chains or straps to keep cylinders from falling and breaking valves

Keep gases that do not mix well apart

Use gas monitors to find leaks early

Storing cylinders the right way and following safety rules keeps people safe from fire, toxic gases, and low oxygen.

Tip: Always follow safety rules and check cylinders often to stop accidents.

Image Source: pexels

Gas cylinder safety labels tell people what is inside. They also show how to use the cylinder safely. Labels must have important details. These include the identification number and serial number. The label also lists the owner and date of maintenance. You can find the tare weight and contents on the label. There is a tracking barcode too. For medical gases, only a few use color to identify them. Most medical gases use clear stickers near the neck. These labels help workers follow safety rules. They also help meet OSHA requirements. Always check the label before you move or use a cylinder.

Color codes help people see what type of gas is inside. They also show the hazard class. Different countries and companies use different colors. Workers should not trust color alone. For example, red often means flammable. Yellow shows toxic or corrosive. Light blue means oxidizing. Bright green marks inert gases. The color shows the hazard, not the exact gas. Always read the label and check the markings. This makes sure you know what is inside. This helps keep handling and storage safe.

Tip: Never use a cylinder just because of its color. Always check the label and markings first.

A good compressed gas cylinder safety program keeps people safe. It should include hazard identification and risk assessment. Control measures are important too. Workers should use engineering controls like ventilation. Gas detection systems help find leaks. Administrative controls are also needed. These include written safety rules and signs. Personal protective equipment is important. Safety glasses and gloves protect against leaks. Only trained people should handle cylinders. Training teaches about hazards and emergencies. It also covers safe handling steps. Always store cylinders upright and use chains to secure them. Keep them away from heat and cars. Separate full and empty cylinders. Never store cylinders in lockers. If there is a leak, move the cylinder outside. Tag it and follow emergency steps. Regular reviews and training keep everyone safe.

Factories and shops use compressed gas cylinders every day. Workers need these cylinders for welding and cutting metal. Many jobs use gases like oxygen, acetylene, and argon to join or cut metal. The food industry uses carbon dioxide to keep food fresh and make drinks fizzy. Water plants use chlorine gas to clean water. Mining companies use cylinders to power tools and give air underground. Steel plants need lots of oxygen and other gases to make metal. These cylinders help keep work safe and fast.

Hospitals and labs use compressed gas cylinders for many jobs. Medical workers use oxygen cylinders to help people breathe. Nitrous oxide helps with pain during surgery. Labs use many gases for tests and research. Safe use is very important in these places. Some key steps are: 1. Keep cylinders from falling over. 2. Make sure labels show what is inside. 3. Only let trained people use cylinders. 4. Use cylinders where air moves well. 5. Keep cylinders away from fire or heat. 6. Use valve caps and working regulators. 7. Close valves and let out pressure after use. 8. Store oxygen and nitrous oxide away from flammable gases. 9. Use special tools for oxygen to stop explosions. 10. Have emergency plans for dangerous gases. These steps help stop accidents and keep everyone safe.

People use compressed gas cylinders at home and at work for many things. The table below shows some common uses:

| Use Category | Common Applications |

|---|---|

| Domestic (Residential) | BBQ grills, water heaters, fireplaces, stoves, clothes dryers, lighting fixtures |

| Commercial (Industrial) | Propane-powered forklifts, small vehicles, large appliances, food production, water treatment, mining, steelmaking, welding |

Many homes use propane cylinders for cooking and heating. Restaurants and hotels use gases for big kitchen tools and heating. Businesses use cylinders to run machines and keep work going.

Compressed gas cylinders can have inert, flammable, toxic, or oxidizing gases. Each kind has its own dangers. Knowing about these dangers helps stop accidents. It is important to know what gas is inside. Labels must be clear and easy to read. Workers should keep cylinders standing up and check for leaks. Store them away from heat or things that can start a fire.

Always check the label and do not trust color only.

Wear safety gear and make sure it works before using.

Keep valves shut when you are not using the cylinder.

Only people with training should use cylinders.

Learn what to do in an emergency and know who to call.

Doing these safety steps and reading safety data sheets keeps everyone safe at work.

If a cylinder leaks, they should move it to a safe, well-ventilated area. They must keep people away and call trained staff. They should never try to fix the leak themselves.

They should always check the label on the cylinder. The label gives the gas name, hazards, and safety information. Color codes help, but labels give the most accurate details.

Cylinders stay upright to prevent leaks and keep the safety valve working. Upright storage also stops liquid gases from escaping as a liquid, which can be dangerous.

Yes, empty cylinders can still have gas inside. They may also have pressure. People should handle empty cylinders with care and store them safely.

Workers should wear safety glasses, gloves, and sturdy shoes. Some gases need special masks or face shields. Safety gear protects workers from leaks, splashes, and accidents.

content is empty!

Ruiying was one professional steel and aluminum gas cylinders manufacturer with the ability of research, development...