- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-07-29 Origin: Site

You should keep full gas cylinders away from empty ones. This helps keep your building safe and stops mistakes from happening. If you mix them up, people can get confused. This confusion can cause leaks or even explosions. Both full and empty gas cylinders can fall if not held in place. If they fall, they can break or let out gas. Sometimes accidents happen when safety caps are missing. Accidents also happen when people do not handle cylinders carefully. Storing cylinders the right way helps stop accidents. It also helps everyone follow safety rules.

Always keep full gas cylinders away from empty ones. This helps stop mix-ups and lowers the chance of leaks, fires, or blasts.

Stand cylinders up straight and use chains or straps to hold them. This keeps them from falling and causing harm.

Put clear labels on all cylinders. Do not just use color to tell them apart. Always act like each cylinder is full and unsafe.

Keep oxygen and flammable gases in different places. Make sure there is fresh air and keep them away from heat or sparks. This helps stop fires and keeps people from running out of air.

Follow safety rules from OSHA and other groups. Teach workers what to do and check cylinders often. This keeps everyone safe and helps you avoid big fines.

You need to think about fire and explosion when storing gas cylinders. Keeping full and empty cylinders together makes fire and explosion more likely. If you mix oxidizers and flammable gases, a fire or explosion can happen. Never let cylinders fall or get damaged. If a cylinder falls, it might release high-pressure gas. This can make the cylinder shoot across the room. It can hurt people and break things.

Tip: Always use chains, straps, or brackets to stop cylinders from falling.

Keep oxygen and other oxidizers at least 20 feet from flammable gases. If you cannot do this, use a fire-resistant wall. Always keep cylinder caps on when storing them. This keeps the valves safe and helps stop leaks or fires. Store cylinders away from heat, wires, and anything that could start a fire. These steps lower fire and explosion risks and help keep everyone safe.

Storing full and empty cylinders together can confuse people and make things more dangerous.

Always label and separate cylinders to stop mistakes.

Storing cylinders the right way helps you follow safety rules and stops accidents.

You can face serious asphyxiation hazards if gas leaks in storage areas. Some gases, like nitrogen or argon, are not poisonous, but they can push out oxygen. Breathing air with less oxygen can make you sick or even cause death. Leaks from empty cylinders can still lower oxygen, especially in small or closed rooms. You might not notice the danger until it is too late.

Toxic gases like carbon monoxide or hydrogen sulfide can also cause asphyxiation. These gases stop your body from using oxygen. If you work near gas cylinders, you should know the signs of asphyxiation. These are trouble breathing, feeling sick, feeling sleepy, or passing out. Always store cylinders where air moves well. Use gas detectors and fans to keep the air safe. OSHA rules say you must secure cylinders, check for leaks, and teach workers about dangers and what to do in emergencies.

Gases like nitrogen and argon can push out oxygen and cause asphyxiation.

Even empty cylinders can leak gases that lower oxygen.

Small spaces make asphyxiation more likely because gases can build up.

Always check air quality and follow safety rules for small spaces.

You need to know about chemical incompatibility when storing different cylinders. Some gases react with others and make new dangers. For example, storing flammable gases with oxidizers can cause a fire or explosion. Toxic gases can get even more dangerous if they mix with other chemicals or get too hot.

| Incompatibility Issue | Description | Recommended Safety Measure |

|---|---|---|

| Flammable gases with oxidizers | Risk of fire or explosion, possible toxic gas release | Keep them apart by hazard class; keep at least 3 meters apart or use barriers that do not burn |

| Toxic gas cylinders exposed to heat | Risk of explosion from pressure build-up | Store away from heat; keep away from industrial heat |

| Oxygen cylinders near flammable gases | High risk of fire or explosion | Store oxygen at least 20 feet away or use gas cabinets |

| Empty cylinders mixed with full cylinders | Confusion and higher risk | Label and separate by hazard class |

Always check the Safety Data Sheet (SDS) for each gas. The SDS tells you about dangers and special storage needs. Store toxic gases in gas cabinets or fume hoods. Keep pyrophoric chemicals away from flammable, combustible, or oxidizing gases. Label all cylinders clearly and follow the supplier’s storage instructions. These steps help you stop chemical reactions and keep your workplace safe from hazards of gas cylinders.

It is important to know which cylinders are full or empty. Clear labels help stop dangerous mistakes. Mixing up full gas cylinders and empty gas cylinders can be risky. You might use the wrong gas by accident. You could also connect an empty cylinder where pressure is needed. This can cause leaks, fires, or explosions.

A good labeling system keeps everyone safe. The best ways use strong labels, tags, and careful storage. Here is a table with common labeling methods:

| Labeling System/Practice | Description and Effectiveness |

|---|---|

| Permanent Labels/Stencils | Strong marks on cylinder shoulders show what gas is inside and do not come off easily. |

| Tags for Empty Cylinders | Tags or “MT” marks help you spot empty gas cylinders fast. |

| Color Coding | Not always reliable because companies use different colors and caps can be changed. |

| Segregation of Empty Cylinders | Store empty gas cylinders away from full gas cylinders to stop mix-ups and dangers. |

| Marking Unknown Contents | Mark unclear cylinders as “contents unknown” and follow what the maker says. |

| Safety Practices | Treat every cylinder like it is full to avoid mistakes from wrong labels. |

You should follow rules like American Standard Method Z48.1 and CGA Pamphlet C-7 for marking compressed gas cylinders. These rules help keep your workplace safe and neat.

Note: Do not trust color coding alone. Always check the label or tag before you move or use any cylinder.

Empty gas cylinders are not really empty. They still have some pressure and may hold dangerous gases. Always treat empty gas cylinders with care. If you ignore the risks, someone could get hurt or things could break.

Empty gas cylinders usually have some pressure left, often about 14.7 psi or more.

Never let compressed gas cylinders go all the way empty. Keep at least 25 psi to stop air or water from getting inside.

Even a little gas can cause fire, explosion, or toxic danger.

If a cylinder falls and the valve breaks, it can shoot across the room.

Both full gas cylinders and empty gas cylinders can fly if damaged.

Rust can make cylinders weak, so leaks or breaks are more likely.

Always store empty gas cylinders standing up and tie them so they do not fall.

Cylinders marked empty have caused accidents when not handled right. If the valve breaks, the pressure can send the cylinder flying fast. This can hurt people or break things. You must treat all compressed gas cylinders, even empty ones, as if they are still dangerous.

⚠️ Always keep empty gas cylinders in a different place and mark them well. Never think a cylinder is safe just because it says empty.

You need to keep gas cylinders apart to stay safe. Always put full cylinders in one spot and empty ones in another. This helps stop mix-ups and accidents. Put clear labels on every cylinder and use signs for each area. Do not just use color to tell them apart. Labels should say what is inside and if it is dangerous. If a label is missing or broken, mark it as “Contents Unknown” and do not use it.

Keep cylinders standing up and hold them with chains or straps. This keeps them from falling over. Give each kind of cylinder its own place. Keep oxygen cylinders at least 20 feet from fuel-gas cylinders, or use a wall that stops fire. These rules come from OSHA and NFPA. Teach workers how to handle cylinders and what to do in an emergency. Good storage keeps fire, explosions, and bad chemical reactions from happening.

Use labels that are easy to read.

Hold cylinders upright with chains or straps.

Mark and set up storage areas.

Teach workers safe ways to store and handle cylinders.

Make your gas cylinder storage area safe. Pick a place that is dry, clean, and has good air flow. Good air flow stops dangerous gases from building up. Keep the area cool and away from heat, fire, or wires. Only let trained people go in. This keeps the area safe and lowers the chance of accidents.

Use racks or stands to keep cylinders standing up. Put straps above the middle of the cylinder. Put safety caps on when you are not using the cylinders. Keep oxygen and fuel-gas cylinders apart like the rules say. Keep the room cooler than 100°F. Put up warning signs and keep Safety Data Sheets close by. Make sure there is enough room to move cylinders safely.

Tip: Always check the rules from OSHA, NFPA, and the Compressed Gas Association to make sure you are doing things right and keeping your workplace safe.

Safe gas storage means planning ahead, keeping cylinders apart, and following all the rules. When you set up your storage area the right way and use good habits, you help stop accidents and keep everyone safe.

You have to follow strict rules for storing gas cylinders. These rules keep your workplace safe and help you avoid big mistakes. Groups like OSHA, NFPA, and the Compressed Gas Association make the main rules for gas cylinder storage. Here are some important things you must do:

Only trained people can go into cylinder storage areas.

Store cylinders standing up and use straps or chains to hold them.

Put the straps above the middle of the cylinder.

Always keep full cylinders away from empty ones.

Make sure storage areas are clean, dry, and have good air flow.

Keep the temperature inside below 100°F (38°C).

Put safety caps on cylinders when you are not using them.

These rules help you follow the law and lower the chance of accidents. U.S. DOT rules add more steps for moving cylinders, like special labels and driver training. International rules, like ISO, sometimes let you use higher pressure and keep cylinders longer. U.S. rules focus more on safety and how you move cylinders. If you follow these rules, you stay safe and protect everyone.

If you do not store cylinders the right way, you can face big dangers. Bad storage can cause serious problems, like:

Cylinders can break or valves can get damaged, which can make gas come out fast and turn cylinders into flying objects.

Oxygen can get pushed out, which can make it hard to breathe.

You can be exposed to gases that are toxic, flammable, or very cold.

Cylinders that look empty may still have gas and need careful handling.

Heavy cylinders can fall and hurt someone.

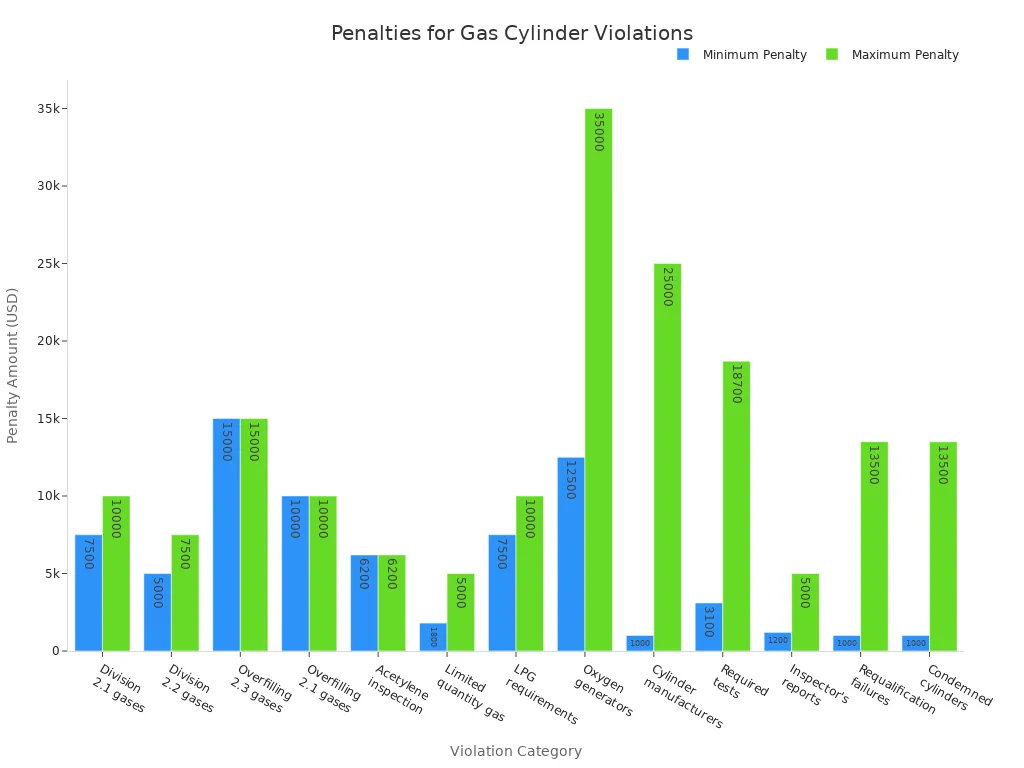

You could also have fires, explosions, or chemical burns from some gases. Accidents can happen if you put cylinders near heat, in rooms with no air flow, or close to things that can burn. Many places get in trouble for these mistakes. If you break the rules, you can get big fines. You might have to pay up to $37,500 each day for every mistake. If you break the rules on purpose, you could pay even more or go to jail. The table below shows some common mistakes and what they cost:

| Violation Category | Specific Violation | Penalty Range |

|---|---|---|

| Division 2.1 gases | General violations | $7,500 to $10,000 |

| Division 2.2 gases | General violations | $5,000 to $7,500 |

| Overfilling cylinders (Division 2.3 gases) | Overfilling cylinders | $15,000 |

| Failure to check daily pressure of acetylene cylinders or keep records | Inspection and record keeping | $6,200 |

| Offering unapproved oxygen generators for transport | Transportation violations | $12,500 to $35,000 |

If you store cylinders badly for a long time, it costs more money. You might have to buy new cylinders more often. Gas leaks can waste gas and make people sick. Accidents can hurt people, damage things, and cost a lot to fix. Training your team and following all the safety rules helps you stop these problems and keeps everyone safe.

You keep yourself and others safe by storing full and empty cylinders apart. Safety experts say this stops fires, explosions, and mixing gases by mistake. Always tie cylinders down, put labels on them, and follow OSHA rules.

Checking cylinders often helps you find damage before it hurts anyone.

Training classes show you how to use, store, and check cylinders the right way.

| Training Topic | Benefit |

|---|---|

| Safe storage | Lowers the chance of accidents |

| Emergency procedures | Gets you ready to act fast |

Pay attention, keep learning, and always put safety first.

You could get confused and make mistakes. Someone might grab the wrong cylinder or not see a leak. This can cause fires, explosions, or let out toxic gas. Always keep full and empty cylinders in different, clearly marked spots.

Look at the label or tag on the cylinder. Do not trust the color by itself. Some cylinders have pressure gauges to help you check. If you are not sure, mark it as “contents unknown” and do not use it.

Empty cylinders still have some gas and pressure inside. They can leak or be dangerous if dropped. Always treat every cylinder like it is full to stop injuries or accidents.

Always keep cylinders standing up and hold them with chains or straps.

Put full and empty cylinders in different places.

Keep them away from heat and things that can start a fire.

Only let trained people handle cylinders.

Groups like OSHA, NFPA, and the Compressed Gas Association make the main safety rules. You must follow their rules to keep your workplace safe and avoid getting fined.

content is empty!

Ruiying was one professional steel and aluminum gas cylinders manufacturer with the ability of research, development...